11 - Maintenance Facility Operations

The golf course maintenance facility is not only the working heart of the property, but also the place for employee training, equipment maintenance, and storage of chemicals, fertilizers, fuel, and many other maintenance items.

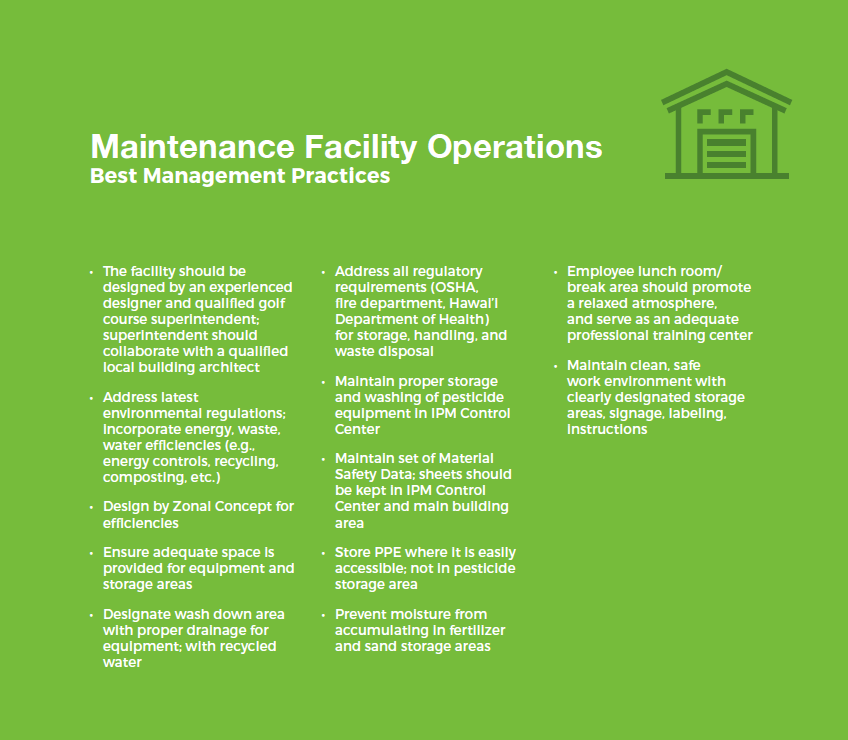

The golf course maintenance facility (GCMF) is one of the most important components of any golf course maintenance operation. The facility should be designed by an experienced designer and qualified golf course superintendent. It would be beneficial to visit other state-of-the-art facilities to gather ideas for design efficiency.

Each of the areas highlighted in this section is aimed at reducing environmental liability and exposure. Depending upon your geographic location and local regulations, you can design your own GCMF. These guidelines are based on an average 18-hole golf course maintenance operation. Photos selected to demonstrate focus areas have been selected from existing certified Signature facilities.

LOCATION

Location can contribute to decreasing fuel consumption, maintenance crew travel time, and excessive equipment wear. Ideally the complex should be located as close as possible to the first and tenth tees; it is even more productive if it can be near the center of the golf course. Designate the GCMF site as early as possible in overall site development of the property and retain a minimum of 1.5 acres of usable land. The GCMF could require more space depending on number of holes or total maintained turf acres. Different parameters need to be considered relative to a golf course with home sites versus no home sites, public or private, heavy play or light play, etc.

DESIGN BY ZONAL CONCEPT

Because resources and capital funds are precious, every square inch of the GCMF must have a specific function, be efficient in relationship to all other zones, and achieve the goal for which it was designed. Consider the following zones:

equipment maintenance area - equipment manager’s office and parts storage

equipment storage

equipment wash down

fuel island

tool storage - shovels, rakes, wheel barrel, etc.

IPM Control Center - pesticide storage, mix & load, rinseate recycling building

fertilizer storage

soil storage

nursery green

composting area

soils laboratory - can serve as a resource library and storage for videos and supplies

master irrigation control room

irrigation parts storage

closet storage space (mops, brooms, vacuum, cleaning supplies for use in GCMF)

golf course supplies storage (non-maintenance - ropes, flag poles, cups, signs, etc.)

employee lunch room - also serves as a training/meeting center

employee restrooms

employee locker room and showers

uniform storage area

office support staff area and files space

assistant golf course superintendent's office

golf course superintendent's office

employee and guest parking

waste disposal

EQUIPMENT MAINTENANCE - MECHANICS WORKSHOP & OFFICE AREA

This area should be segregated from general employee activity areas and equipment storage. An experienced golf course equipment mechanic, along with the golf course superintendent, should be involved in designing this zone. Equipment is repaired and serviced in this area so adequate space for oil changes, reel grinding, and other service related jobs must be allocated. An assortment of lifts (portable, flush floor mounted and beam supported) can be distributed in the appropriate areas of this zone to facilitate moving all types of equipment and reduce the risk of back injury.

Collier’s Reserve, Naples, FL

An overhead lube center (grease/oil dispensers supported by compressed air and connected to bulk drums) is convenient, uses overhead rather than floor space, and stores large drums out of the general view and work area. Shop necessities such as empty gas cans, towels and miscellaneous supplies, other than equipment parts, can be stored in cabinets distributed throughout the shop area for convenience. Ensure all combustible products and materials are stored properly in fire resistant cabinets.

Large work benches with underneath storage provide for work space at waist level (as opposed to working from the floor) and can decrease risk of back fatigue and injury. An adjoining air conditioned office with adequate parts storage bins, desk, computer, files and phone. Consider including a shatter-proof window facing the shop area to allow the mechanic a full view of the shop from the office. A sink and blower type hand dryer needs to be available in the shop.

Hasentree Golf Club, Wake Forest, NC

EQUIPMENT MAINTENANCE & STORAGE AREA

Equipment used to apply pesticides and fertilizers should be stored in areas protected from rainfall. Rain can wash pesticide and fertilizer residues from the exterior of the equipment, and these residues can contaminate soil or water. Pesticide application equipment can be stored in the chemical mixing center, but fertilizer application equipment should be stored separately. Blow or wash loose debris off the equipment to prevent dirt from getting on the CMC pad, where it could become contaminated with pesticides.

Other equipment should be stored in a clean, safe and protected area when not in use. Every piece of equipment should have a designated spot, delineated by yellow or white lines, with its name or number and should be parked in the same spot every day. This allows for immediate identification of equipment if it develops a leak (oil, hydraulics, etc.) and increases accountability for maintaining premium operating condition. Use solvent-recycling machines or water-based cleaning machines to cut down on the use of flammable and/or toxic solvents. Use a service to remove old solvents and dispose of them properly.

A complete list of equipment needed to properly maintain the golf course must be developed. The exact size of all the equipment is important to appropriate the right amount of space needed.

The design should allow for all equipment to be driven in and out of the storage area without having to move other equipment. A superintendent who is experienced in the daily golf course maintenance program will be able to help design a floor plan for equipment storage to minimize unnecessary "shuffling."

Several overhead doors on both sides of the equipment storage area allow for a smooth transition of equipment entering and leaving the building and provide good air flow. Overhead fans in the equipment storage zone facilitate air flow and help reduce hidden moisture on equipment.

Waste oil should be collected from the equipment and stored in a container which is set on containment. If stored outside, there should be a roof over the container and a valve in the bottom of the containment to release rain water.

Since this is not generally a work space, it is also an excellent zone for the shop compressor, eliminating the loud running sound in a personnel work area. The compressor should be located away from walls adjacent to an inside wall where sound could penetrate and be disruptive.

EQUIPMENT WASH DOWN AREA

Depending on current regulations, and size of operation, a combined fuel island and equipment wash-down area may be most productive and cost effective. Do not wash equipment unnecessarily. Clean equipment over an impervious area, and keep it swept clean. Brush or blow equipment with compressed air before, or instead of, washing. Use spring shutoff nozzles.

For a separate wash-down area, the following considerations should be taken into account:

Water used to clean equipment should be potable water (as opposed to brackish or other)

Water used to wash equipment should be recycled and contaminating materials such as grease, oil, and gasoline need to be filtered from recycled water.

Closed loop water recycling systems with a proven track record should be utilized.

Pesticide equipment should not be washed off in this area; it should be washed at the IPM Control Center.

A roof should cover the wash-down area to keep rain off the pad and prevent excessive water from going into the recycling storage tanks; the roof also serves as a sun shade for the crew during cleanup to reduce sun exposure.

Pad should be elevated to direct rain water away from the wash-down area.

Roof should be high enough to allow golf course equipment or fuel trucks proper clearance, yet low enough to meet aesthetic requirements (visibility to homeowners, etc.).

Several air hoses attached to posts prior to the wash-down pad can be used to remove excessive grass residue from equipment prior to moving onto the wash-down pad. This reduces grass clippings/debris entering the water recycling system.

Pad should have triple screen baskets, weighing less than 40 pounds each, to prevent excess grass clippings and debris from entering the recycling system.

Hoses with attachable spray bottles of liquid wax at the wash-down pad can be utilized so valuable equipment can receive a brief application of liquid wax (put with water) after each use.

Concrete in the pad should be impermeable to prevent leaching of contaminates.

Install lightning protection for worker and equipment protection.

Do not use brackish water (which could be detrimental to equipment).

FUEL ISLAND

This zone should be located at least 80 feet from the main building and preferably combined, or working in conjunction with, the wash-down pad. Cover the fuel island to minimize sunlight on equipment, as well as degradation of hoses and fuel tank filters; also to minimize increased evaporation of fuel and provide protection for employees. Critical items for the safe and efficient operation of the fuel island zone are:

Install adequate lighting around and beneath the roof to allow for operation during periods of darkness or inadequate light.

Install lightning protection on the fuel island roof.

Unless otherwise required by law, all fuel storage and carrying mechanisms should be above ground devices.

Fuel should be stored in above ground, double vaulted tanks from a reputable manufacturer (such as Convault)

The fuel island pad should be concrete and recessed from normal ground level to allow for containment in the event of a fuel spill; the recession should be deep enough to contain a few hundred gallons of spillage but not so severe that it presents difficulty for equipment entering and leaving the fuel island.

Being able to load fuel from both sides of the storage tanks cuts down time that employees spend waiting to fuel up.

Prior to construction, Fire Marshall and other appropriate authorities should review specifications.

Bollards should be placed near the tank and at other areas that could be hit and damaged by mowers or other equipment.

Storage of fuel onsite during construction should follow guidelines for protection of water bodies, ground water, HIOSH, OSHA, and the local fire department.

Tanks should be placed within containment and loading zone should be contained as well.

Fuel management systems provide additional safeties, accountability and theft controls.

Fuel Storage and Loading During Construction

Fuel brought onto a dirt site in a stand-alone tank should be set in containment. This can be as simple as digging a shallow hole the size of the tank and covered the hole with a tarp or bladder. The tank would be placed on this tarp.

IPM Control Center (formerly referred to as chemical/pesticide storage building)

This is an important zone where pesticides will be stored, mixed, and recycled. The following features are critical to an efficient and environmentally sound IPM Control Center:

Control center should be at least 200 feet from the main body of NRMC, if possible; one end of NRMC houses the fuel island and the opposite houses control center

Control center should be at least 100 - 200 feet from a body of water or well

A complete alarm system, with battery backup, for burglary or fire

Locks and bolts used at control center should be of highest quality materials

Materials used inside the control center are comprised of high quality durable plastic, aluminum, or concrete to avoid absorption of chemical residues or vapors

Install explosion proof fan and explosion proof lighting

Ventilation design must be an integral part

Locate all pesticides stored on non-absorbent shelving at least 6" off floor

Segregate pesticides by liquid, powder, or granular class

Store powders and granules above liquids

Shelving must be sturdy and secured to avoid sagging and falling

Slope floor toward center of the room with a recessed sump located at its center

Construct floors of seamless metal or concrete sealed with chemical resistant paint

Locate light/fan switch outside door of CC to turn on before anyone enters and turn off after exiting

Install stainless steel sink with potable water, spigot, and hand blower (not paper towels) with drainage funneled back into the sump

Attach mixing table to the sink at a slightly higher elevation to allow overspill to be washed into the sink

Locate portable eye wash bottle over the sink; immediately outside, an eye wash/shower station supplied by potable water should be installed

Locate a refill hose above the sump to allow proper and timely filling of spray tanks with water

Only qualified personnel should be allowed access to the control center

Beneficial to install a hot water heater in the control center to aid in the dissolving of water soluble products

No wood should be used within the pesticide control center

The sprayer should be stored within the pesticide control center

Maintain a set of SDS; sheets should be kept in this location and main building area

Store PPE where easily accessible; not in pesticide storage area, as it may be inaccessible in an emergency

FERTILIZER STORAGE ZONE

This zone could share the same building as the IPM Control Center but needs to be segregated by a solid concrete wall and a solid metal door (preferably rust-proofed).

If the building housing the fertilizer is metal, then steps should be taken to protect the metal building from degradation by fertilizer (such as adding painted plywood around the walls).

The building should be big enough to allow a small forklift to deliver fertilizer by pallet. If not, a pallet jack could be used to place the fertilizer in the room. Spreaders could be hung on the wall and the use of a dehumidifier would be beneficial in protecting the fertilizer from water absorption.

SOIL STORAGE ZONE

This area could be immediately adjacent to the fertilizer storage zone and should have a roof, although it need not be any higher than 12 feet. It does not need to be tall enough for a 22-ton dump truck to deposit sand, top dressing, or rock. More efficient use of the space is achieved by depositing the material immediately outside the storage bins and then pushing the material into the bin with a front-end loader.

It is important to keep this area covered to prevent rain from dampening the material and wind from dispersing weed seeds into the top dressing. The block walls segregating sand, top dressing, and rock should be filled solid with concrete. If possible, the opening should face away from prevailing rains or a durable drop cloth should be used to cover the opening. Ceiling fans could be installed overhead to help reduce moisture retention in the top dressing or sand.

This area is developed to have a ready supply of the exact grass cultivar maintained on the actual greens playing surface. It can be used for the repair of damaged areas on greens surfaces. An average 18-hole course could utilize from 3,000 to 6,000 square feet for the nursery green.

NURSERY GREEN

The nursery receives the same cultural treatments as the course greens and should be located in close proximity to the GCMF. It can be used for training new greens mowers, cup cutters, and for testing new cultural products. It is also used as a valuable teaching tool for practice putting by the maintenance staff to demonstrate how a quality green and its cut interact; and demonstrate the importance of a properly installed cup on the putting surface.

IRRIGATION CONTROL ROOM

The computer for the golf course irrigation system and storage shelves or cabinets is housed here with a lockable door.

STAFF & VISITOR AREAS

Employee Lunch Room and Training Area

There should be administrative and managerial offices, in addition to an employee lunch room and break area. The break area should promote a relaxed atmosphere and serve as an adequate and professional training center (video training and technical seminars). The size of the crew and the number of holes in the golf operation will determine the appropriate size of the lunch room. Important items to include:

Adequate tables/chairs for dining and training

One or two microwave ovens (prevents long waits to heat up meals)

One adequate sized (energy saver) refrigerator

Drinking water with dispenser, coffee-maker, cold drink vending machine

Kitchen area with sink, water, sufficient cabinet area

Erasable communication board

Air conditioned and insulated, with overhead fans for air flow

Light attractive colors in semi-gloss for easy cleaning and to enhance the atmosphere make the room appear more spacious

Employee Restroom/Locker Room/Shower

Design restrooms to promote superior personal hygiene, ensuring they are easy to clean with adequate space/amenities to service several employees simultaneously. The locker room should be immediately adjacent to the restrooms and incorporate full-length lockers with at least one shower. A semi-gloss, high quality paint should be used for ease of cleaning.

A dry deck type material can be used on portions of the floor to prevent slippage and spread of bacteria. Both of these rooms should be insulated and air conditioned. Hand blowers should be used instead of paper towels.

Numerous considerations can contribute to water, energy, and cost reductions:

Restrict water flow to the maximum necessary for adequate use

Use automatic shut-offs on faucets

Install 1.5 gallon tanks on toilets

Use motion detectors to turn on lights when staff is present

WASTE DISPOSAL AREA

This area should be located away from normal employee activity, but close enough to be reasonably functional. Proper access for waste pick-up vehicles should be incorporated in the design and location of this zone.

Prior to design or renovation of the GCMF the following specialists should be consulted to maximize desired benefits in energy, water, and waste management:

Recycling expert

Energy efficiency expert

Water conservation expert

Composting or waste management expert

Paper, Plastic, Glass, And Aluminum Recycling

Office paper, recyclable plastics, glass, and aluminum should be recycled. Place containers for recycling aluminum cans and glass or plastic soft drink bottles at convenient locations on the golf course.

Composting

Setting aside an area for compost can reduce the amount of grass clippings and debris, such as leaves or routine, healthy landscape trimmings that would normally go to a landfill. With the right expertise, compost can be used effectively to improve the soil for top dressing, non-putting surface areas, donated or sold to offsite vendors. Do not compost diseased material, as this may spread disease. Extensive research should be

done before addressing this beneficial process.

HAZARDOUS MATERIALS DISPOSAL

Ensure all containers are sealed, secured, and properly labeled. Use only FDEP-approved, licensed contractors for disposal.

Pesticide Containers

Empty pesticide containers are classified as hazardous wastes if not properly rinsed, and as a result would be subject to regulations governing hazardous waste. Federal law (FIFRA) requires pesticide applicators to rinse all empty pesticide containers before taking other container disposal steps. Under the federal Resource Conservation and Recovery Act, or RCRA, a pesticide container is not empty until it has been properly rinsed. The improper disposal of a hazardous waste can result in fines and/or criminal penalties. Pesticide containers that have been properly rinsed can be handled and disposed of as nonhazardous solid waste.

Used Oil, Antifreeze, and Lead-Acid Batteries

Collect used oil, oil filters, and antifreeze in separate marked containers and recycle them. Oil filters should be drained (puncturing and crushing helps) and taken to a place that recycles used oil, or to a hazardous waste collection site. Gas stations or auto lube shops may accept small amounts (including filters). Antifreeze must be recycled or disposed of as a hazardous waste. Commercial services are available to collect this material. Lead-acid storage batteries are classified as hazardous wastes unless they are recycled. Used acid from these batteries contains high levels of lead and must be disposed of as hazardous waste, unless the acid is contained within a battery being recycled. Make sure all caps are in place to contain the acid. Store batteries on an impervious surface and preferably under cover. Spent lead-acid batteries must be recycled if they are to be exempt from strict hazardous waste regulations. Do not mix used oil with used antifreeze or sludge from used solvents.

Solvents and Degreasers

One of the key principles of pollution prevention is to reduce unnecessary use of potential pollutants. Over time, the routine discharge of even small amounts of solvents can result in environmental and liability consequences, due to accumulation of contaminants in soil or ground water. As little as 25 gallons per month of used solvents to be disposed of can qualify as a “small quantity generator” of hazardous waste, triggering EPA and FDEP reporting requirements. Whenever practical, replace solvent baths with recirculating aqueous washing units (which resemble heavy-duty dishwashers). Soap and water or other aqueous cleaners are often as effective as solvent-based ones.

Blowing off equipment with compressed air instead of washing with water is often easier on hydraulic seals and can lead to fewer oil leaks. Store solvents and degreasers in lockable metal cabinets in an area away from ignition sources (i.e., welding areas or grinders), and provide adequate ventilation. They are generally toxic and highly flammable. Never store them with pesticides or fertilizers, or in areas where smoking is allowed. Keep basins or cans of solvent covered to reduce emissions of volatile organic compounds (VOCs) and fire hazards. Keep an inventory of solvents stored and the MSDS’s for these materials on premise, but not in the solvent storage area. Keep emergency response equipment recommended by the manufacturer of the solvent in a place that is easily accessible and near the storage area, but not inside the area itself.

Follow OSHA signage requirements. Always wear appropriate PPE, especially eye protection, when working with solvents. Never allow solvents to drain onto pavement or soil, or discharge into waterbodies, wetlands, storm drains, sewers, or septic systems, even in small amounts. Solvents and degreasers should be used over a collection basin or pad that collects all used material. Most solvents can be filtered and reused many times.

Store collected material in marked containers until it can be recycled or legally disposed of. Solvent disposal private firms provide solvent washbasins that drain into recovery drums and pickup service to recycle or properly dispose of drum contents. Collect used solvents and degreasers, place them into containers marked with contents and date, and then have them picked up by a service that properly recycles or disposes of them. Never mix used oil or other liquid material with used solvents. Use only FDEP-approved, licensed contractors.